The number of prestigious boat

Intrigued about this company, we have decided to discover this Italian industrial excellence and, to do that, we have gone directly to the source, that is one of the two Amare Group’s factories. The goal is to provide you with an overview of the company and get closer to those who, every day, contribute to make it sail fast.

At first glance, once we get the factory situated in the industrial area of Pozzilli in the province of Isernia, Italy, we are impressed by the wide surface which it extends over. Order and cleanliness characterize spaces, offering an excellent entrée.

Michele doesn’t waste time and takes us to the assembly area. Here, we are immediately catapulted into the heart of the company and, proudly, he tells us: ” Amare Group holds many patents it has got not only thanks to its finished products but also thanks to the mechanisms that guarantee its functioning”.

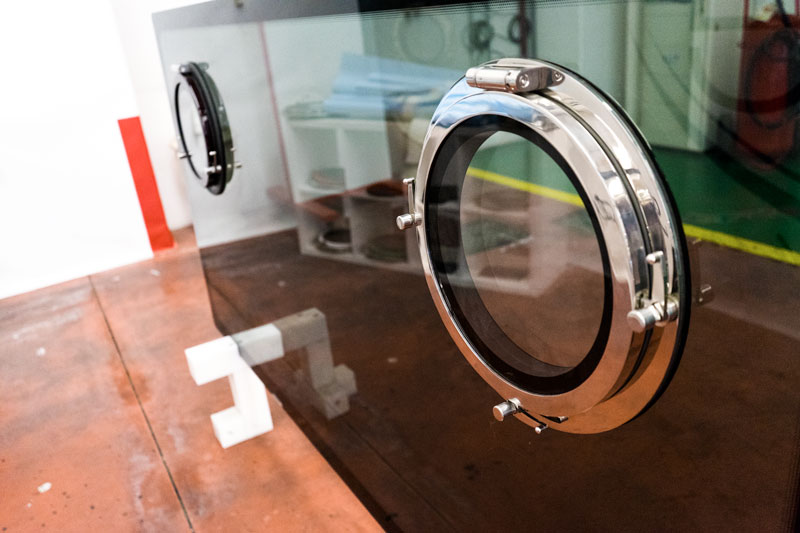

We immediately understand the reason for his statement because the first thing we see is the assembly process of a friction hinge. It’s a patented mechanism that controls the opening of portholes, especially those installed on the portholes of the Infinity series.

This mechanism results into excellent sturdiness and solid operating cycles, reducing any possible breaks as demonstrated by several tests. We try to open one of these hinges and it works perfectly, the mechanism offers the right resistance and keeps the porthole steady in the selected position. Thanks to this hinge, flapping portholes are just a thing of the past.

Then, an area full

Noticing our intrigued glaze, Michele explains that some of them are parts of Vision, the electrically-operated pop-up window that fits the gunwales of many luxury yachts.

Others, instead, are the glass windows the company has received by some among the most prestigious boat manufacturers, such as Ferretti, Azimut and Riva that send them directly to Amare’s establishments so that technicians can install portholes. What we are looking at, Michele explains, belong to Riva shipyard and will be mounted on the new Riva 66 Ribelle.

The time required for the gluing process must be respected with precision. Technicians, all with specific certifications that enable them to carry out their delicate work, put the portholes on the glass and glue them through a multi-step chemical welding process. It’s a complex process, whose result must be perfect both from an aesthetic point of view and in terms of structural and water tightness. Checks by Amare’s operators are carried out on both incoming and outgoing glasses.

During our tour, Diego Ruggiano, Business Manager of Amare Group, joins us. He is the best person to explain us how the company interacts with its own customers. He says: “Amare wants to work in close contact with its customers. It’s the only way the company can learn and internalize important knowledge, customizing its own products according to the specific needs of every single client”.

We find ourselves before a really impressive

The model we are looking at is designed to fit boats from 100 feet in length and is being tested right now. Kindly, technicians show us its operation and, I must admit it, when seen out of its natural position in stern of a boat, it really looks like a “beast”!

All product tests,

Packaging, too, requires the same attention. Special anti-stratch films are applied on the most delicate parts of products before delivery.

We conclude our tour with a visit to the steel carpentry department. This area is completely separated from the others. Here, technicians assembly and weld the various parts of products. The department also deals with hand polishing. This way, the company avoids the opacification that is typical of industrial polishing, which clearly suggests the great attention payed to a product that must inevitably be perfect.

Analyzing Amare Group’s productive environment, “very high quality” is the concept which everything revolves around. We have observed a right mix of industrial and artisanal manufacturing, both essential to create unique and valuable products.

Together with its products, the Amare Group brand is a young reality, rich of fresh ideas and responsive to change. Its main goal is to build modern-designed, luxury and custom accessories that are increasingly more innovative than competitors’ ones.

One Response

Good afternoon! I attended your exhibit at the Messe in Amsterdam last year. I am currently in the process of replacing the glazing on my yacht and would like to order portholes from you that could be installed in a double-glazed unit. Please send a calculation of the cost for one porthole and possible production times. Best wishes! Mikhail Chistyakov.