Much of the recent evolution in yachting design  results from the introduction of new accessories and the chance for numerous manufacturers and designers to broaden the horizons of possibilities . It is no coincidence that architect Ludwing Mies van der Rohe’s famous dictum was “God is in details”.

results from the introduction of new accessories and the chance for numerous manufacturers and designers to broaden the horizons of possibilities . It is no coincidence that architect Ludwing Mies van der Rohe’s famous dictum was “God is in details”.

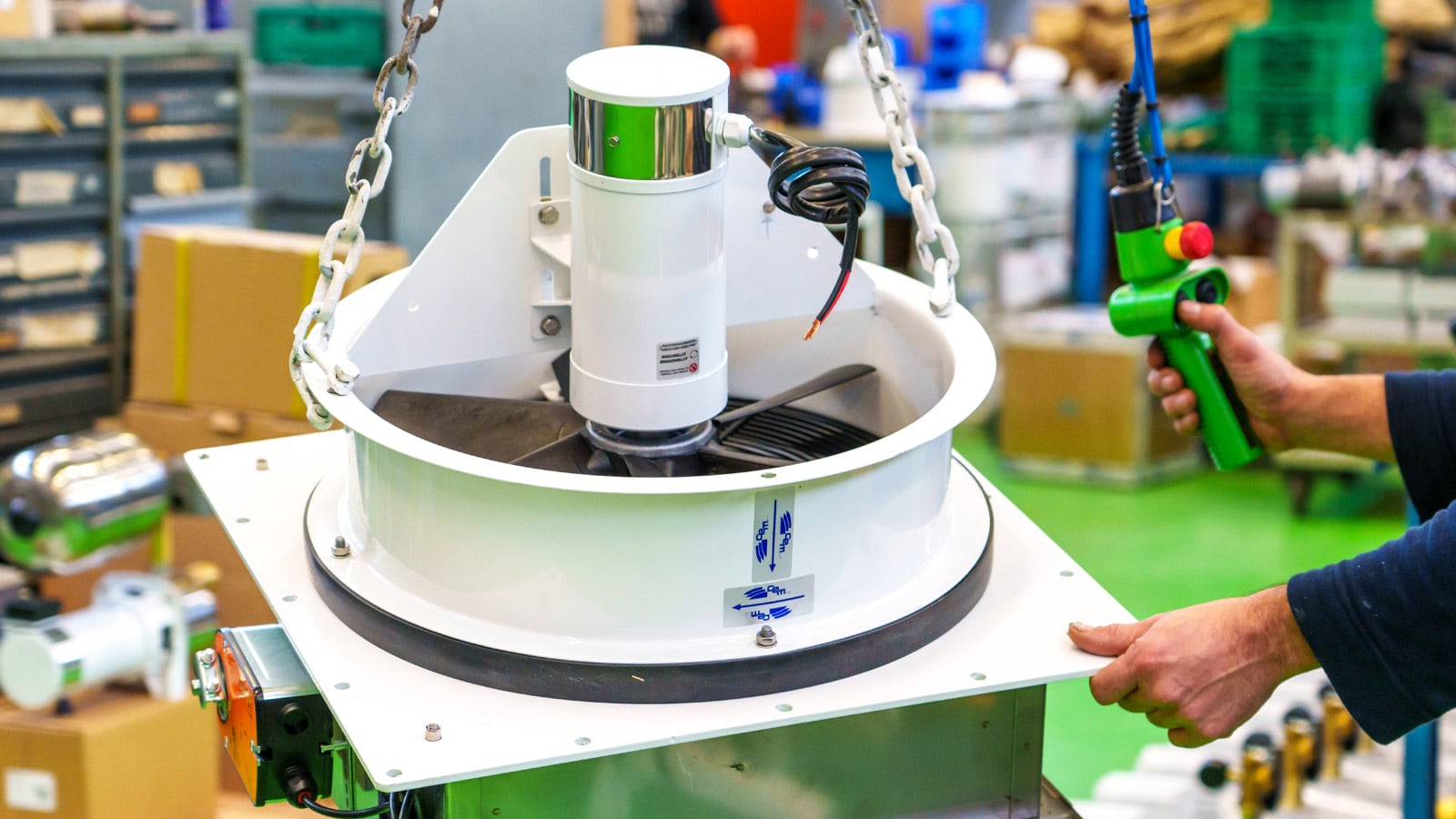

Over the last few years, just a few things have been so distinctive as yacht terraces with opening bulwarks, convertible transoms that can be easily transformed into submergible bathing platforms or retractable gangways that, despite an extension up to 7 metres, can be folded into compact compartments when not in use.

A key role in this innovation process is played by Besenzoni, an Italian company based in Sarnico, one among the most iconic places of high-quality Italian yachting industry. Founded in 1967 and specialized in the manufacturing of prime boat accessories, Besenzoni currently boasts 100 employees in addition to a wide network of local suppliers, all sons of a region that has built its wealth on steel manufacturing.

Over the past three years, 9% of company turnover has been reinvested in innovation: a great percentage if we consider that the EU average is around 2% (and the figure is much more significant if compared with the Italian reality where this value drops to 1.2%). Furthermore, Besenzoni Research &

The history of the brand started with Giovanni Besenzoni,

The list of products is even longer and includes more advanced systems, such as folding helipads (currently under inspection by some aviation safety authorities) or drone platforms. In short, a multitude of products designed to suit the most various needs.

– Fiorella, what do customers look for in a boat accessory?

” Invention engenders notoriety and draw customers’ attention. However, what makes the customer feel safe is the solidity of the business itself. Of course, we’re pleased that a helm seat of ours – the P 400 Matrix – has gained the nomination for the Dame Award – the prestigious competition hosted by METS, the world’s largest leisure marine equipment trade show – but what makes us feel much more satisfied is the certainty that customers look at us as a reliable partner for their needs”.

This means that products need not only to be new and attractive but also increasingly more “plug and play” and user-friendly. A company like Besenzoni has indeed to interact with different kinds of clients, including private owners, designers, boat manufacturers, project managers and even captains. Needs, too, are different: while some customers look for attractive design, others focus on easy installation, reliability and assistance network extension.

” Price is a common concern of all customers. Clients who “spare no expense” are a rare exception. I can’t recall more than three”, the manager tells us.

For all these reasons, an ambitious company should focus on each of these aspects to preserve its position within the market. This results in the need to develop products that can be as comprehensive as possible in

Of course, the needs of the shipyard that has to install a specific accessory represent an important priority. 80% of Besenzoni yacht accessories are destined to be installed during a building or refitting process.

” Post-sale market consists exclusively of external gangways, table supports and helm seats”, Fiorella explains, “ The capacity of establishing a stable co-operation with a shipyard since the very first boat development and construction steps represents an additional guarantee for our industrial customers because we give them the solution to all their problems. In addition, we optimize our products or invent something new, if necessary”.

However, it’s only after installation that the life of an accessory actually begins. Demanding conditions, including moisture, salinity and uninterrupted motion, result in severe test for the resistance of complex systems like those ones made in the Sarnico-based production site. And if Murphy’s law – “Anything that can go wrong will go wrong” – is true, companies should always be ready to offer efficient assistance services. Moreover, boat accessories inevitably tend to travel all around the world: after all, yachts sail…

” When your assistance network includes 185 help centres in 59 different countries, slack seasons don’t exist: alternating seasons in the two hemispheres result into the possibility to enjoy summer and cruises in different places. Consequently, the only solution is to be operational, always. And “always” means “always”, holidays included. A boat holiday ruined by an accessory failure is never a good thing”.

” It’s important to focus on those customers who climb on board a boat just once or twice a year: they generally look

” Innovative in terms of design and technology, the world of yacht accessories remains conservative in terms of materials“.