Surface propellers are a concept established over forty years ago, representing a significant evolution in motor boating. This innovation is credited to Italian engineer Buzzi, who in 1975 designed adjustable surface propellers. In 1979, Howard Arneson, another enthusiast of speed, pioneered Arneson surface drives.

We visited Luca Radice, a highly seasoned expert in propellers, who helped us gain a better understanding of how this crucial accessory functions.

How do surface propellers function, and what are their characteristics?

The premise is that surface propellers can be mounted on boats with a certain power; otherwise, it makes no sense to apply them. They are designed specifically to allow the boat to reach high speeds, but they are entirely useless without adequate engine power.

The concept itself is quite simple: to increase speed, it is necessary to reduce resistance. The resistance to the forward movement of a boat is due to two factors: wave resistance and frictional resistance. Surface propellers work half immersed and half out of the water, utilizing cavitation effects to increase speed when the propeller is not submerged, thereby reducing friction.

The profile is designed to operate under conditions different from traditional propellers that are constantly submerged. In the case of surface propellers, cavitation must necessarily occur to exploit increased pressure on the blades. During their emergence from the water, they trap air, which generates greater thrust and faster rotation.

Which material is more suitable, bronze or steel?

It’s an interesting discussion; almost all steel propellers are made of AISI316 with high strength, but this means they cannot undergo further changes once cast. The advantage of bronze, such as our alloy Mibral which reaches 75/80kg/mm2 of strength, approaching the 90 kg/mm2 of 17-4ph steel, is that bronze propellers have a resistance very similar to steel. They allow machining with 5-axis machines and, importantly, they have elasticity in elongation which steel does not. For example, hitting a log in the sea with a steel propeller may result in losing a blade due to its brittleness. With bronze, a blade may bend, but the cruise can still continue.

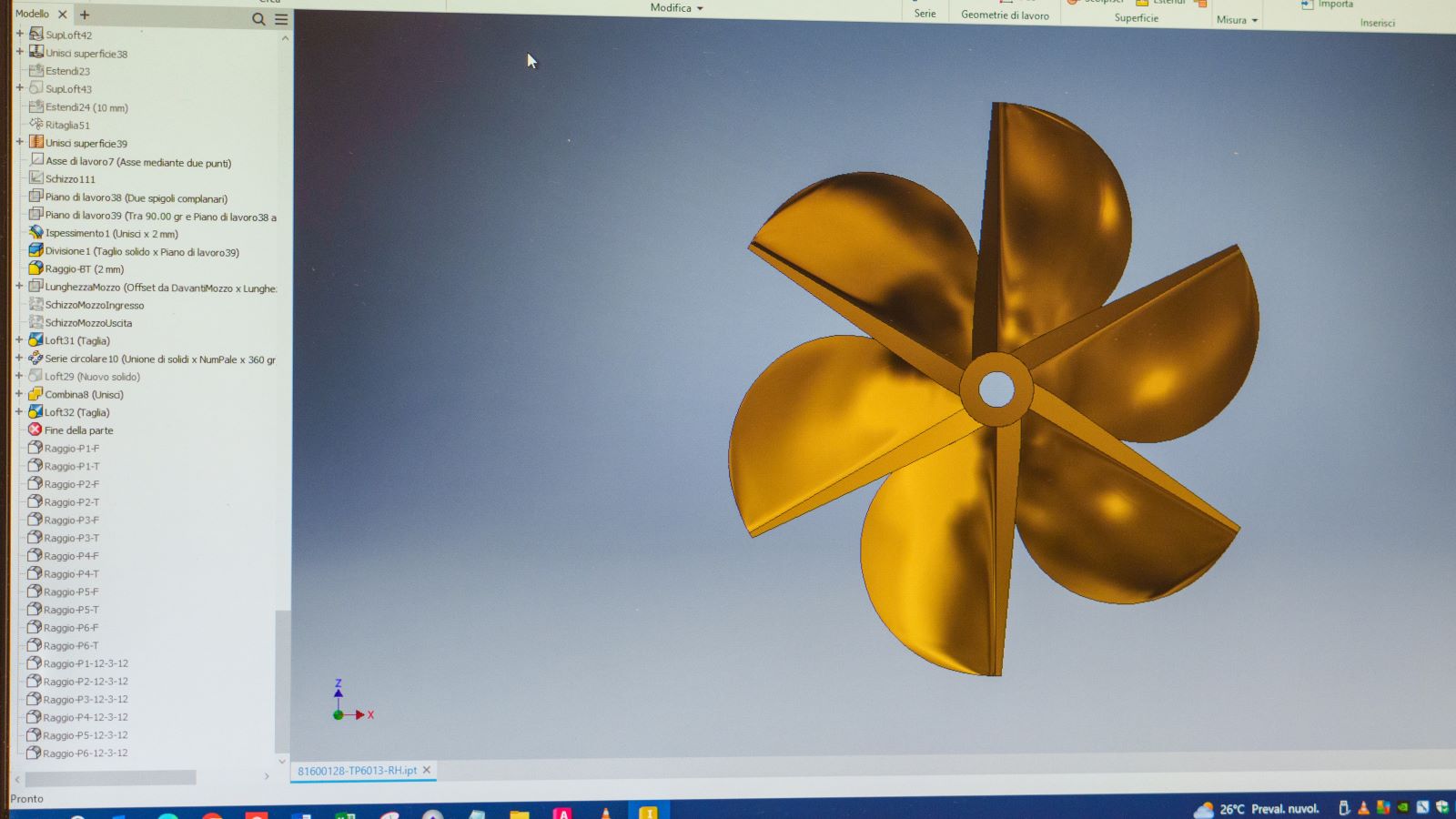

How are surface propellers designed?

The basic concept is to establish performance; today, programs calculate propellers with virtually no errors, almost like an exact science.

The challenge lies in sizing them, not only in diameter but also in thickness to withstand continuous stress. Eliche Radice has developed an exclusive in-house software for surface propellers that tests durability in the lab and determines the optimal thickness for best performance.

Performance and differences between one choice and the other?

It’s difficult to answer because a boat designed with surface propellers is meant for this purpose. The advantage lies in having no appendages in the water, resulting in less resistance during movement. As mentioned earlier, this allows for achieving high speeds while reducing fuel consumption. If the goal isn’t speed, opting for a traditional propulsion system is probably better.

About Eliche Radice

ELICHE RADICE is a company with over a hundred years of history and today boasts having the entire production chain within its own facilities, allowing complete control over the entire process from material arrival at the foundry to delivery. Continuous company inspections and verifications ensure that products are of excellent quality, which is undoubtedly one of the key factors that has enabled the company to become a leader in the market.