“There are only two companies in Italy that are able to switch from an aluminium block to a complete engine. One is Ferrari, the other is Selva Marine”.

It is with this statement that our journey inside the Selva Marine factory in Tirano begins. And the words spoken by Carlo Selva, a member of the fourth generation of the Selva family, are definitively strong.

Especially if we consider that Selva Marine operates in a sector, namely the engine motors sector, that is increasingly controlled by large Japanese and American multinational companies. It is difficult to compete with these giants but Selva, thanks to its production capacity and its high quality standard, has done much more.

The company,

This is a clear demonstration of how the efficient realities of Made in Italy can stand out and compete “on equal terms” in the global market.

Returning to Carlo Selva’s words and to his comparison, we can say that, unlike Ferrari that we have never visited, we can certify Selva with great pleasure.

Here, in fact, like in an episode of How it’s made, we saw with our own eyes how an aluminium block can turn into an outboard engine.

How is an outboard engine born?

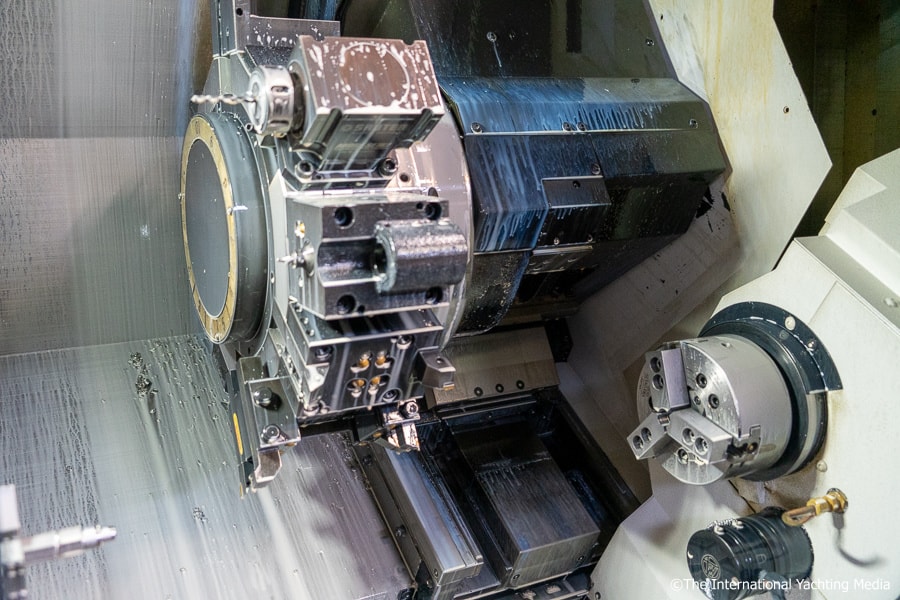

Some pieces have complex shapes and require precision machining. For these reasons, they are processed directly in the mechanical workshop where some turning machines of different sizes work at full speed. Some of them are technological and can work even on a transverse axis but, of course, require careful digital programming.

Once the shape

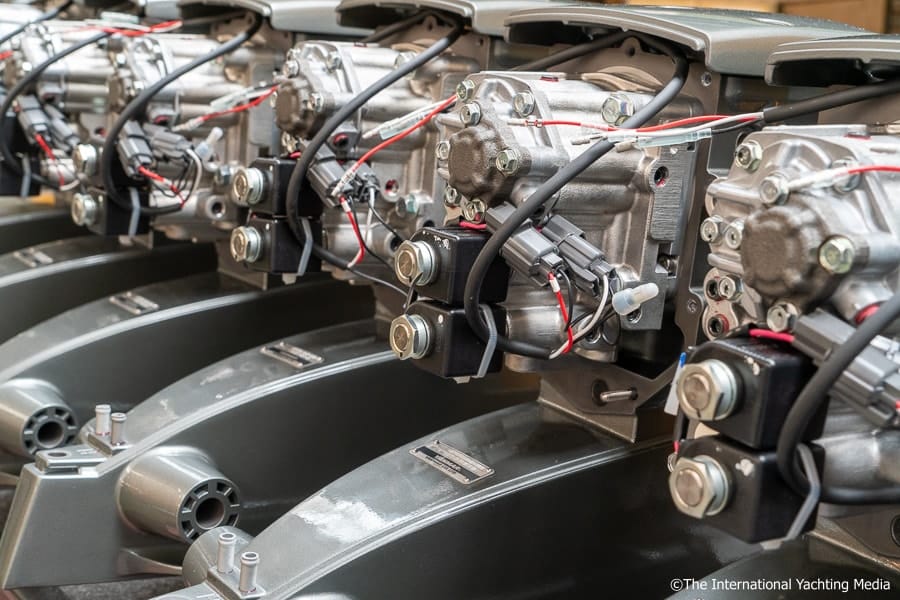

At this point, the parts are sent to the assembly department.

The latter is situated in the span of the factory. Here, the parts are first tested and then assembled as needed.

An aspect that impressed us was that the department is surrounded by hundreds of jigs and templates of different shapes and sizes. Accumulated over decades of activity, these templates are used to facilitate the processing of products and are a source of price for the company since they are made in-house.

Moreover, the company

Finally, in the testing room, the engines are tested in order to analyze their power and polluting emissions. This is a very important step for the purpose of certification. The room houses a series of tanks where the engines are placed as if they were in water. The room is also used as a laboratory to test the development of innovative products. What is developed inside is often secret, we can’t reveal what we saw but we can say that new ideas seem to have found their natural habitat here.

Carlo tells us with a smile that he has lost track of how many they are; every brand and every country require a specific one. This results into an important and demanding commitment that, of course, is also the best guarantee of how high the level of quality expressed by this Italian company is.

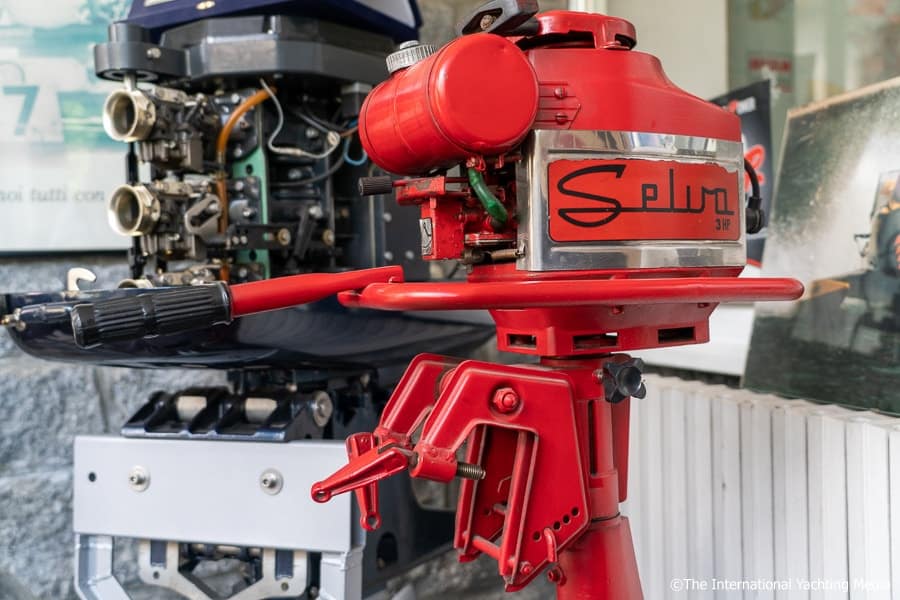

Selva Marine’s history

The economic boom of the

In the post-war period, the company manufactured, in its factory of Sesto San Giovanni, mechanical parts for some historic Italian car manufacturers. In the same period, the famous motor boat driver Ezio Selva sailed with an outboard made by his family factory.

In 1959, the founder of the company, Lorenzo Selva, experienced some troubles with some of his traditional automotive customers and decided to change his business. So, he moved the production to Tirano, where marine engines became the core business of the company together with the sale of motor yachts and RIBs.

Today, after more than 50 years of history, Selva Marine is still run by the Selva family and is an international company that can create an outboard from zero through a completely in-house production cycle.

Selva Marine

Viale dell’industria 13 – 23037 Tirano (SONDRIO)