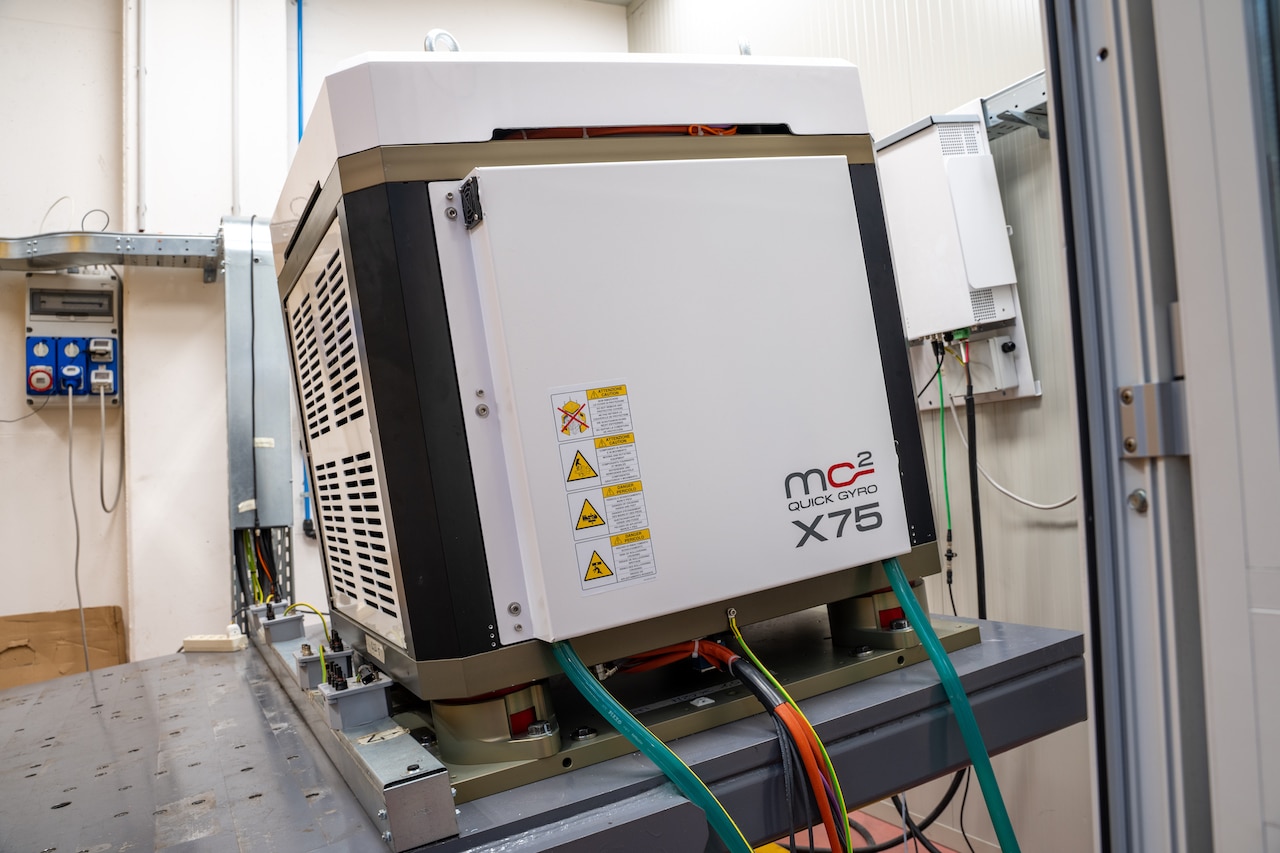

The X75 is the most powerful and innovative gyro stabilizer ever produced by Quick. In order to better understand how such a “great” result has been achieved, we interviewed Fulvio Romano, Operations Director, and Chiara Marzucco, Vice President of this well-known Italian multinational company.

The result was a very exciting and useful technical conversation, which satisfies both the curiosity of owners and captains and the information needs of those who are responsible for building the wonderful super and mega yachts we are used to telling you about.

From this meeting with the company’s top management, it is clear that the strategy is to meet the demands of the refit and initial installation market for large yachts and recreational boats, areas that the company is looking at with increasing attention.

Thanks to the development of the new X75, Quick’s overall market coverage has also expanded, and it now meets the demands and needs expressed by shipyards launching super and mega yachts. This is a segment that increasingly requires multiple installations of gyroscopic stabilizers, while also demanding smaller dimensions and ease of installation during the construction phase, or afterwards, all requirements that the X75 is able to satisfy in a surprising way.

With the X75 comes the most̀ powerful stabilizer ever produced by Quick. What does this choice represent in terms of development and innovation?

The stabilizers market is constantly evolving, as is the demand from boat builders and owners that tend to move towards larger boats year on year. With the X75 we wanted to extend the Quick Gyro range upwards with the birth of this new stabilizer which, although it resembles the X56, has a completely different technological content.

With X75 we have been able to increase by 35% the straightening power against a negligible increase in size, the size on board increases in fact only 5%, a simply amazing result that, to be achieved, has required the implementation of new technological solutions, different from the rest of the range.

For example, the system for controlling the braking profile and releasing the stabilizing torque in the boat is completely new and required the development of purpose-built electronics, both in terms of the technology used and the development of dedicated software.

To ensure our now famous product reliability, we used our established R&D process for the new X75. We started with a preliminary analysis of the key requirements for this type of machine, followed by the study of the engineering, both basic and detailed, which enabled the development and testing of prototypes, and finally the launch of the product into production, a phase that in Quick only takes place once testing has been completed.

75,000 Newton meters of straightening power is a lot, so what type of yacht/superyacht can the X75 stabilize?

The machine is designed to work in single installation on yachts and superyachts from 20 to 30 meters. With the multiple installation technique, which has many advantages, we can easily equip even 50-meter yachts.

The X75 is 30% smaller than its competitors. How did you achieve this result?

We have achieved this thanks to the architecture of our stabilizers, which is still unique in the market.

We therefore do not need to create a vacuum, the mechanics of which would unnecessarily increase the size of the stabilizer (and its complexity).

We have also equipped some components of the machine with a special liquid cooling system that is less sensitive to the problem of galvanic currents, thus solving a very important problem for super and mega yachts.

In simpler words?

Thanks to the choice of configuration of the horizontal axis, the technological leeway with respect to both mechanical and thermal stresses allows the creation of a simpler, more reliable and easier to maintain machine. The Anglo-Saxon proverb applies: “What doesn’t exist doesn’t break”.

Refitting, first installation, or both? Which markets are you mainly thinking of?

We are targeting both markets, the refitting market which benefits enormously from the compactness of this machine, but also the first installation market where, thanks to the small size of our stabilizers, a lot more space is freed up for livable boat interiors.

Have you already installed your first stabilizer? On which yacht?

We are installing Quick Gyro X75 in multiple configuration on a 40-meter, almost 400-tonne gross tonnage vessel.

What kind of compatibility does this product offer with on-board electronics and/or smartphones?

Like the rest of the range, the Quick Gyro X75 can also be interconnected via QNN, the gateway that allows the entire ecosystem of Quick products to be brought onto the on-board electronics, particularly the navigation screens, from which it can be directly controlled. This applies to both a single stabilizer and a multi-stabilizer system.

Is there an App?

We have a real App that can give a report on the performance of the machine in terms of roll correction, comparing the data obtained with the gyro off and then on at a given sea condition.